My Video on IG through link below.

https://www.instagram.com/reel/C9fQ3xegiuc/?utm_source=ig_web_copy_link

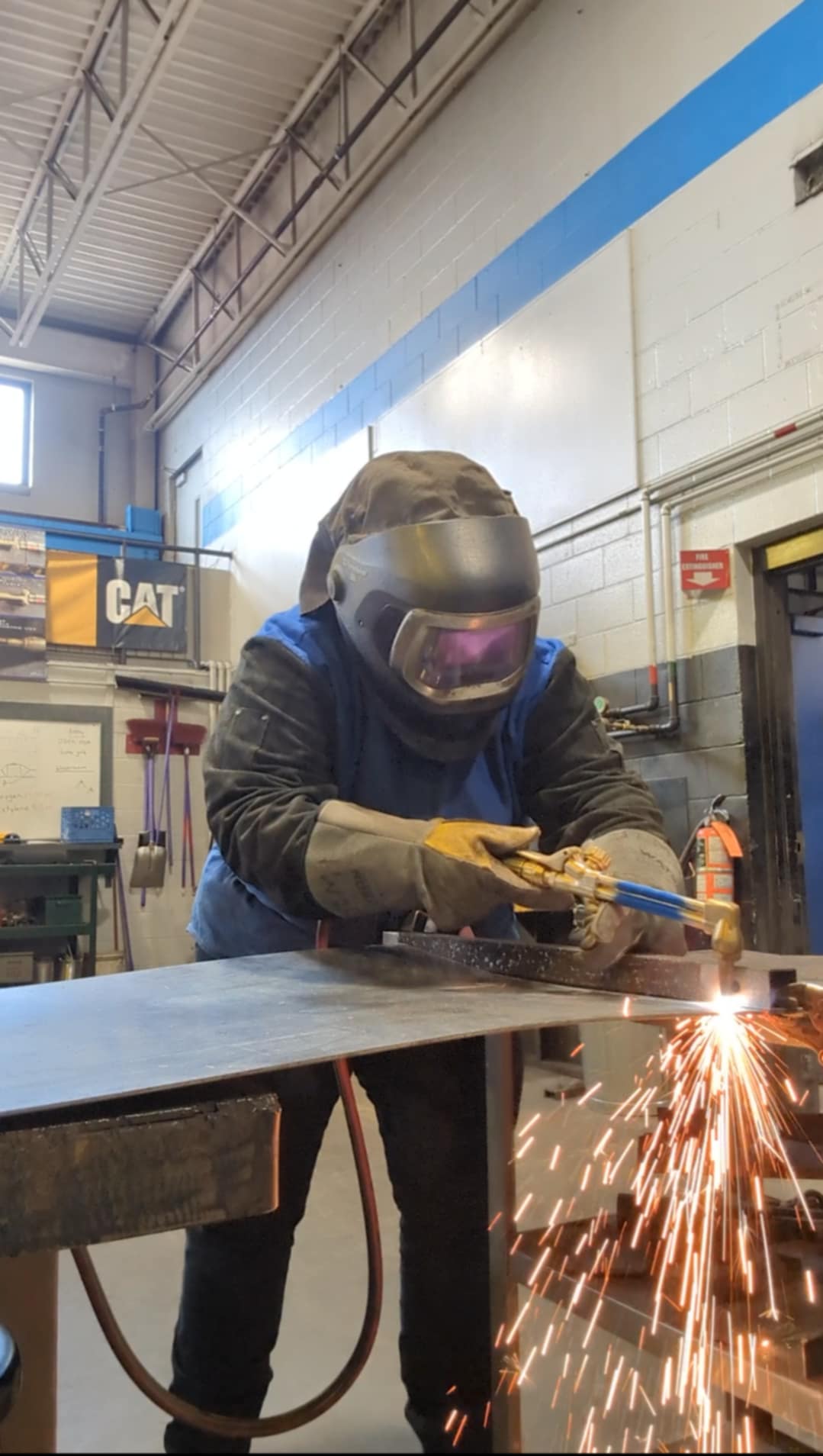

The tip is too big for the job.

Seems to be how everyone does it… At least that’s what the Motive Power apprentices tell me from their perspective.

It’s no coincidence that the Stars weren’t aligned… The cut did not go smoothly from start to finish. Some minor setbacks did occur well honing in travel speed. Quality of cut reduced. The minor dross was easily whacked off… Still. Cleaned up with a grinder.

Was this acceptable for this scenarios?

Maybe, maybe not…

On the operation side:

Setting the torch to the size of tip it is holding is correct operation.

Messing with pressures because material doesn’t match tip would be unsafe operation to try to accommodate a larger tip cutting a thinner part.

However,

If you set the proper pressures for the tip in use, other parameter changes can take place during process to accommodate, slightly.

We know big tips will cut small things!

The question is quality level desired.

That’s whatever meets acceptance criteria for that particular application.

Moreover,

Production increases by streamlining processing.

Like why give someone the wrong tool so they have to get another tool to clean it up before the next step can take place…

Or potentially more likely for discontinuities to occur.

That leads to repair work which then triples at least the production time. AND $$$$$$$$$$$$$$$$$$¢

We can’t forget that the people operating the equipment are upset about it all because they got to do it three times over.

And half the problems could have been averted with using the right tool in the first place.

Pay for the tools…

Work it into the price…

Whether it’s the company that pays for it or the service provider I swear there’s a way to write this tool off whatever it is. PRACTICE, good employer practices.

HELPS EMPLOYEES Happiness, productivity, life, etc…

Should be paid for in pride of work alone… because you are so VALUED… IF you put in the honest time and give yourself the credit you deserve for being the ethical person you are.

GRATEFUL FOR YOU, thank you for doing a job you love, well.

Or as well as you can in the situations.

JEMI

P.S. Reminder, material thickness dictates tips size, tip size dictates pressure. Follow manufacturer recommendations for SOP’s of the equipment you are using.

Safe working My friends.

#weldtech #Modern.JEMz #oxyfuelcutting